bunched up ground wires in electrical box The inspector failed us because all the grounds were not tied together in a 2 gang switch/ receptacle box. The box is plastic and contains a lighting circuit and a small appliance . Welding titanium sheet metal requires precision, skill, and a deep understanding of the unique properties of this remarkable material. As a professional welder with years of experience, I've honed my techniques to ensure optimal results when working with titanium sheets.

0 · junction box ground wiring

1 · how to connect ground wires together

2 · grounding wires under panels

3 · grounding wire under lugs panel

4 · grounding wire requirements

5 · grounding wire for box box

6 · ground wires from separate circuits

7 · double up grounding wires under lugs

With a Japanese car, I doubt any of the sections on the car are 1.2mm. That is classic car thickness, not modern car metal. 1.0mm sheet will be plenty! ;-) 1.2mm is easier to .

What's the best way to connect a ground wire to my new occupancy switch? I was attempting to cut off the crimp, but read online that . Inspected a main service panel where whoever wired the panel had “saved space” by pigtailing three branch circuit ground wires together inside the panel so each pigtailed . The inspector failed us because all the grounds were not tied together in a 2 gang switch/ receptacle box. The box is plastic and contains a lighting circuit and a small appliance . I just passed my rough-electrical inspection on the house I'm building but the inspector made me promise to crimp together the ground wires in each electrical outlet box .

A grounding bar kit will include two screws which mount the new bus directly to the chassis. You can purchase one (either Cutler-Hammer or Eaton) at any hardware store, home . You definitely need to connect all the switches and the box to the equipment grounding conductor (EGC - often referred to as the "ground" wire). The whole purpose of .

Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) .You notice how the ground wire is stranded and not one solid piece of copper wire like the white one above? This means it's probably attached to the back of the box and most likely that's it. .

12v battery junction box

Learn how to calculate box fill accurately for efficient and safe wiring. Enhance your electrical knowledge with this formal guide. What's the best way to connect a ground wire to my new occupancy switch? I was attempting to cut off the crimp, but read online that all ground wires should be crimped/grouped together. That box is too deep into the wall. You will need a box extension sleeve to correct it. Instead of a crimp, use a wire nut. Inspected a main service panel where whoever wired the panel had “saved space” by pigtailing three branch circuit ground wires together inside the panel so each pigtailed bunch could be connected to the neutral/ground bar via one ground wire. In fact, I noticed a number of doubled-up wires. I believe that this box allows two grounding wires under a single lug. I know that two neutrals are not allowed.

The inspector failed us because all the grounds were not tied together in a 2 gang switch/ receptacle box. The box is plastic and contains a lighting circuit and a small appliance branch circuit. In this instance I kept the equipment grounds from the 2 circuits separate. I had cases of so many grounds I can't fit them all under one wire nut. But I don't see an issue of bundling 3 or 4 of them under one nut, then taking another one the same size as the largest in the group, and using it to tie to another wire nut with the rest of the grounds. I just passed my rough-electrical inspection on the house I'm building but the inspector made me promise to crimp together the ground wires in each electrical outlet box (where there are 2 or more ground wires). It was the only thing I didn't know I was supposed to do before he came out. A grounding bar kit will include two screws which mount the new bus directly to the chassis. You can purchase one (either Cutler-Hammer or Eaton) at any hardware store, home center, or electrical supplier.

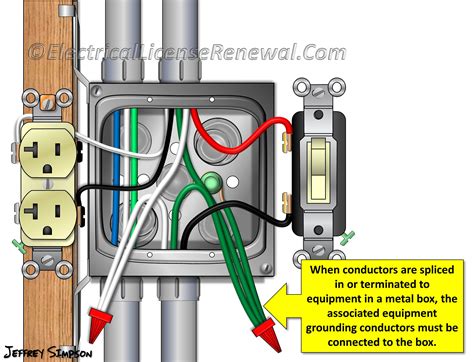

You definitely need to connect all the switches and the box to the equipment grounding conductor (EGC - often referred to as the "ground" wire). The whole purpose of bonding (connecting) these things together is to provide a low resistance path back to .

Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) standards. Be sure to check local codes before performing any wiring job.

You notice how the ground wire is stranded and not one solid piece of copper wire like the white one above? This means it's probably attached to the back of the box and most likely that's it. You need the ground to go from the panel and through each cable to each box. What's the best way to connect a ground wire to my new occupancy switch? I was attempting to cut off the crimp, but read online that all ground wires should be crimped/grouped together. That box is too deep into the wall. You will need a box extension sleeve to correct it. Instead of a crimp, use a wire nut. Inspected a main service panel where whoever wired the panel had “saved space” by pigtailing three branch circuit ground wires together inside the panel so each pigtailed bunch could be connected to the neutral/ground bar via one ground wire. In fact, I noticed a number of doubled-up wires. I believe that this box allows two grounding wires under a single lug. I know that two neutrals are not allowed.

The inspector failed us because all the grounds were not tied together in a 2 gang switch/ receptacle box. The box is plastic and contains a lighting circuit and a small appliance branch circuit. In this instance I kept the equipment grounds from the 2 circuits separate.

I had cases of so many grounds I can't fit them all under one wire nut. But I don't see an issue of bundling 3 or 4 of them under one nut, then taking another one the same size as the largest in the group, and using it to tie to another wire nut with the rest of the grounds. I just passed my rough-electrical inspection on the house I'm building but the inspector made me promise to crimp together the ground wires in each electrical outlet box (where there are 2 or more ground wires). It was the only thing I didn't know I was supposed to do before he came out. A grounding bar kit will include two screws which mount the new bus directly to the chassis. You can purchase one (either Cutler-Hammer or Eaton) at any hardware store, home center, or electrical supplier.

You definitely need to connect all the switches and the box to the equipment grounding conductor (EGC - often referred to as the "ground" wire). The whole purpose of bonding (connecting) these things together is to provide a low resistance path back to .

Installing a ground wire to your electrical service panel can be done easily with a few hand tools. The codes of some localities differ from NEC (National Electric Code) standards. Be sure to check local codes before performing any wiring job.

junction box ground wiring

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.

bunched up ground wires in electrical box|grounding wire requirements